Page 55 - ICSE Chemistry 8

P. 55

Crystallisation

The process of separa ng a solid dissolved in a liquid to make a solu on is called crystallisa on. This is

done by warming the solu on and allowing the solvent to evaporate thus leaving a saturated solu on.

We can obtain pure sugar from its solu on in water

by crystallisa on. This is done by hea ng the sugar Know Your Scientist

solu on in such a way that the water evaporates. Robert Boyle (1627–1691): Being the fi rst

When very li le amount of water is le , the solu on modern chemist, Boyle was one of the earliest

is cooled. The dissolved sugar separates in the form of men to apply scien fi c methods in chemistry

crystals on cooling. Crystals are solid par cles having and physics.

defi nite shape and size. The sugar crystals obtained

are cubical and shiny in appearance.

Froth Floatation

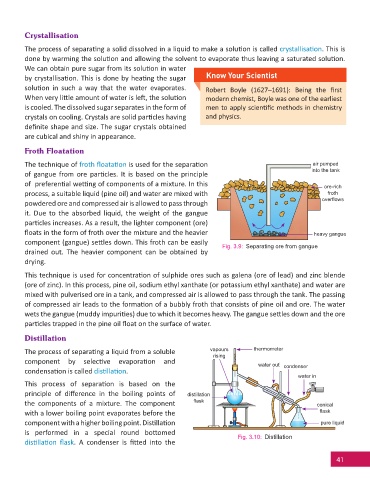

The technique of froth fl oata on is used for the separa on air pumped

into the tank

of gangue from ore par cles. It is based on the principle

of preferen al we ng of components of a mixture. In this ore-rich

process, a suitable liquid (pine oil) and water are mixed with froth

overfl ows

powdered ore and compressed air is allowed to pass through

it. Due to the absorbed liquid, the weight of the gangue

par cles increases. As a result, the lighter component (ore)

fl oats in the form of froth over the mixture and the heavier heavy gangue

component (gangue) se les down. This froth can be easily

Fig. 3.9: Separating ore from gangue

drained out. The heavier component can be obtained by

drying.

This technique is used for concentra on of sulphide ores such as galena (ore of lead) and zinc blende

(ore of zinc). In this process, pine oil, sodium ethyl xanthate (or potassium ethyl xanthate) and water are

mixed with pulverised ore in a tank, and compressed air is allowed to pass through the tank. The passing

of compressed air leads to the forma on of a bubbly froth that consists of pine oil and ore. The water

wets the gangue (muddy impuri es) due to which it becomes heavy. The gangue se les down and the ore

par cles trapped in the pine oil fl oat on the surface of water.

Distillation

The process of separa ng a liquid from a soluble vapours thermometer

rising

component by selec ve evapora on and

water out condenser

condensa on is called dis lla on.

water in

This process of separa on is based on the

principle of diff erence in the boiling points of distillation

the components of a mixture. The component fl ask conical

with a lower boiling point evaporates before the fl ask

component with a higher boiling point. Dis lla on pure liquid

is performed in a special round bo omed

Fig. 3.10: Distillation

dis lla on fl ask. A condenser is fi ed into the

41